Contract Manufacturing for Plastic Parts

Engineering-Led Contract Manufacturing for Complex, Long-Term Plastic Production

When your project demands more than transactional moulding- when forecast-driven supply, audit-ready compliance, recycled content targets, and multi-year production stability are non-negotiable - you need a contract manufacturing partner who takes complete accountability from design through delivery.

Complete end-to-end contract manufacturing

Design, DFM, precision tooling, injection moulding, assembly, packaging - one Australian partner managing your entire production lifecycle

50+ million components annually

With forecast-driven weekly delivery - 10,000 to 1M+ parts per project, structured for $1.2M+ annual partnerships80% recycled content achieved

Across contract manufacturing programs - ACOR Member, Product Stewardship Partner, verified circular manufacturing with full ESG reporting supportTriple ISO (9001, 14001, 45001) + DISP certified

Audit-ready quality systems, IP protection, secure facilities for defence and regulated supply chains2-3 week lead times

For existing tooling migration, complete reshoring support from offshore suppliers, same-time-zone communication18 years supporting Australia's leading brands

Across defence, medical, mining, construction, agriculture, and regulated industries

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Engineering Certainty

Contract manufacturing for plastic parts is the most effective way for Australian organisations to secure reliable, scalable, and compliant production without coordinating multiple suppliers.

For buyers researching how to choose a plastics manufacturer in Australia, the real question is not who can mould parts, but who can manage the entire manufacturing process end to end with engineering control, certified quality, circular capability, and long-term supply confidence.

For projects involving complexity, regulation, sustainability targets, or long production horizons, B&C Plastics operates as an engineering-led contract manufacturing partner rather than a basic moulder. This page explains how contract manufacturing for plastic parts works, what differentiates an end-to-end partner from a commodity supplier, and how Australian manufacturing delivers measurable value when risk, compliance, and continuity matter.

-

Innovative Plastic Manufacturing Solutions

Innovative plastic manufacturing solutions are defined by systems, not slogans. True innovation combines engineering, tooling, injection moulding, automation, and quality management into one accountable operation.

B&C Plastics delivers contract manufacturing solutions that integrate:

+ Engineering-led design and manufacturability analysis

+ Injection molding optimised for repeatable production

+ Advanced tooling designed for long service life

+ Certified quality systems embedded into daily operations

Rather than treating manufacturing as a single step, the entire process is engineered to reduce variation, protect tooling investment, and maintain quality over time. This approach is critical for customers who require consistent plastic parts across months or years of production, not just a successful first run.

-

End to End Plastic Production Services

End to end plastic production services remove friction from the supply chain by eliminating handovers between designers, toolmakers, and manufacturers. For procurement and engineering teams, this reduces risk, improves accountability, and simplifies communication.

At B&C Plastics, end to end production services include:

+ Product design and engineering support

+ Design for manufacture and material selection

+ Tooling design, manufacture, and lifecycle management

+ Injection moulding for low and high volume production

+ Assembly, secondary operations, and packaging

Because all services are delivered in-house, production issues are resolved at the source rather than passed between suppliers. This model is especially valuable for medical, defence, construction, and industrial projects where traceability, audit readiness, and change control are essential.

-

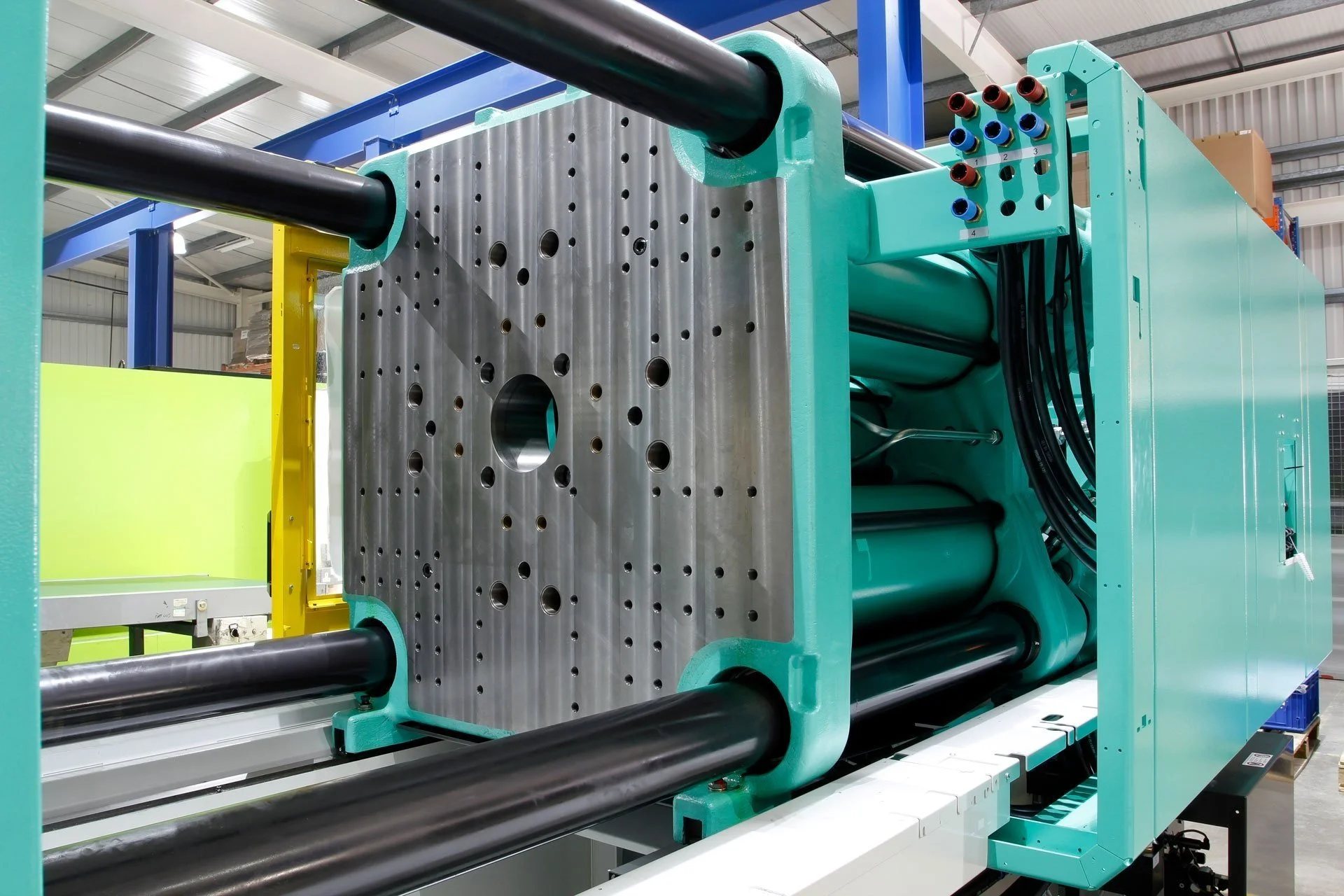

High Performance Injection Moulding

High performance injection moulding focuses on consistency, control, and durability rather than speed alone. The quality of plastic parts depends on tooling design, machine selection, material behaviour, and process control.

B&C Plastics operates a fleet of injection moulding machines ranging from 50t to 600t, supporting a wide range of part sizes, materials, and production volumes. Annual production exceeds 50 million moulded components, delivered under controlled manufacturing conditions.

High performance injection moulding capabilities include:

+ Multi-cavity and family moulds

+ Tight tolerance production

+ Long-run contract manufacturing

+ Controlled process windows for repeatability

This level of control ensures plastic products maintain dimensional accuracy and functional performance across full production lifecycles.

-

Advanced Tooling and Precision Moulding

Tooling is the foundation of successful contract manufacturing. Poorly designed tools create quality issues, downtime, and escalating costs over time.

B&C Plastics applies engineering discipline to tooling design with a focus on:

+ Tool steel selection based on material and volume

+ Optimised cooling and flow paths

+ Maintenance access and lifecycle planning

+ Compatibility with recycled and circular materials

Precision moulding outcomes are achieved not through adjustment after the fact, but through tooling engineered for stability from the start. This protects both the manufacturing process and the customer’s investment.

-

Design, Engineering and 3D Modelling

Design and engineering decisions made before tooling begins determine whether a product can be manufactured efficiently and consistently.

B&C Plastics provides industrial design, engineering, and 3D modelling services that align product intent with manufacturing reality. Engineers analyse geometry, wall thickness, tolerances, and material flow to ensure the design supports injection moulding rather than fighting it.

Key design and engineering services include:

+ 3D modelling and CAD development

+ Design for manufacture optimisation

+ Engineering validation before tooling

+ Material selection based on performance and sustainability

This approach reduces rework, shortens development timelines, and improves long-term production outcomes.

Contract manufacturing at B&C Plastics is designed for organisations that value reliability, compliance, and scalability.

Capabilities include:

Injection moulding for plastic parts

Contract manufacturing for ongoing production

Assembly and secondary operations

Packaging and labelling services

Forecast-driven supply models for customers

Typical contract manufacturing projects range from 10,000 to over 1 million parts annually. For long-term partners, production is scheduled against 12-month forecasts, enabling consistent weekly delivery and stable capacity planning.

Contract Manufacturing Capabilities

Prototyping and Product Development

Prototyping bridges the gap between concept and production. For contract manufacturing to succeed, prototypes must reflect real production conditions.

B&C Plastics supports product development through:

CNC prototyping for functional validation

Low-volume moulding for market testing

Engineering feedback before full tooling investment

By aligning prototyping with future manufacturing requirements, products can scale without redesign or tooling replacement. This is a critical advantage over suppliers who treat prototypes as isolated exercises.

Reshoring and Local Manufacturing Support

Reshoring and local manufacturing support have become strategic priorities for Australian businesses seeking supply chain resilience.

B&C Plastics supports reshoring by:

Migrating existing offshore tooling to Australian production

Re-engineering tools where required

Establishing local quality control and traceability

Reducing lead times to 2 to 3 weeks for existing tools

Local contract manufacturing also reduces hidden costs associated with offshore production, including shipping delays, quality failures, communication gaps, and IP risk. For regulated industries, Australian manufacturing provides a clear compliance advantage.

Serving a Wide Range of Industries

Sector-specific experience matters more than generic capability claims. B&C Plastics supports industries where plastic manufacturing must meet defined standards.

Industries served include:

Defence and secure manufacturing

Medical and healthcare products

Construction and infrastructure

Mining and harsh-environment applications

Agriculture and irrigation

Packaging and consumer products

Each industry has unique performance, compliance, and documentation requirements. Contract manufacturing processes are adapted accordingly rather than applied generically.

Delivering Measurable Value for Clients

Contract manufacturing must deliver measurable value beyond unit cost. At B&C Plastics, value is defined by outcomes that reduce risk and support growth.

Clients benefit from:

Engineering-led manufacturing decisions

Consistent quality across production runs

Reduced supplier coordination and management time

Verified circular and sustainability performance

Predictable lead times and supply continuity

Circular manufacturing is a core differentiator. B&C Plastics consistently achieves up to 80 percent recycled content in suitable plastic products, exceeding current industry targets and supporting ESG and APCO reporting requirements. Circular design principles focus on reduced material complexity, improved recyclability, and long-term environmental performance.

Certifications play a direct role in value delivery. Triple ISO certification supports quality, environmental, and safety management, while DISP approval provides security, IP protection, and audit confidence for defence and regulated supply chains. These credentials are not marketing badges but operational frameworks embedded into daily manufacturing practice.

Frequently Asked Questions

Still looking for answers? Give our friendly team a call on (07) 3208 0544 or pop in for a visit!

-

Contract manufacturing involves outsourcing the full plastic manufacturing process, including design support, tooling, injection moulding, assembly, and supply, to a single specialist partner.

-

Typical projects range from 10,000 to over 1 million parts annually. Long-term partnerships often exceed $1.2M per year in sustained production.

-

For existing tooling, production can often commence within 2 to 3 weeks. New product development projects may require up to 6 months for design, prototyping, tooling, and validation.

-

Yes. Material selection and tooling are engineered to support recycled plastics while maintaining performance and quality.

-

Australian manufacturing offers shorter lead times, stronger IP protection, audit readiness, and supply chain resilience compared to offshore options.

Ready to Start Your Manufacturing Journey

Choosing the right contract manufacturing partner determines whether a plastic product succeeds at scale or struggles under production pressure. For organisations seeking engineering-led manufacturing, circular capability, certified quality, and long-term supply confidence, the decision should be based on systems, not slogans.

B&C Plastics is built for customers who need more than a moulder. The focus is on end-to-end responsibility, measurable outcomes, and partnerships that last beyond the first production run.

Talk to Our Manufacturing Team

If you are evaluating contract manufacturing for plastic parts in Australia, the next step is a conversation about fit. Volumes, timelines, compliance requirements, and sustainability targets all matter.

Contact the B&C Plastics team to discuss your project, request technical information, or assess whether an engineering-led contract manufacturing model is right for your business. The goal is not simply to produce parts, but to build a manufacturing partnership that supports quality, growth, and certainty over the long term.