HDPE Recycling in Australia

Australian HDPE Recycling Engineered For Performance, Not Just Diversion Targets

Closed-loop circular manufacturing with up to 80% recycled content integration, verified mechanical performance, and APCO-aligned traceability - so procurement and sustainability teams meet ESG obligations without compromising product reliability or audit readiness.

Engineering-led material validation before product commitment

Test recycled HDPE against mechanical strength, impact resistance, UV stability, and chemical exposure requirements so performance is verified, not assumed

APCO member + ACOR associate + CRC participant

Active involvement in federal recycling policy, industry standards development, and medical plastics waste solutions that position your supply chain ahead of regulatory changesUp to 80% recycled content in suitable applications

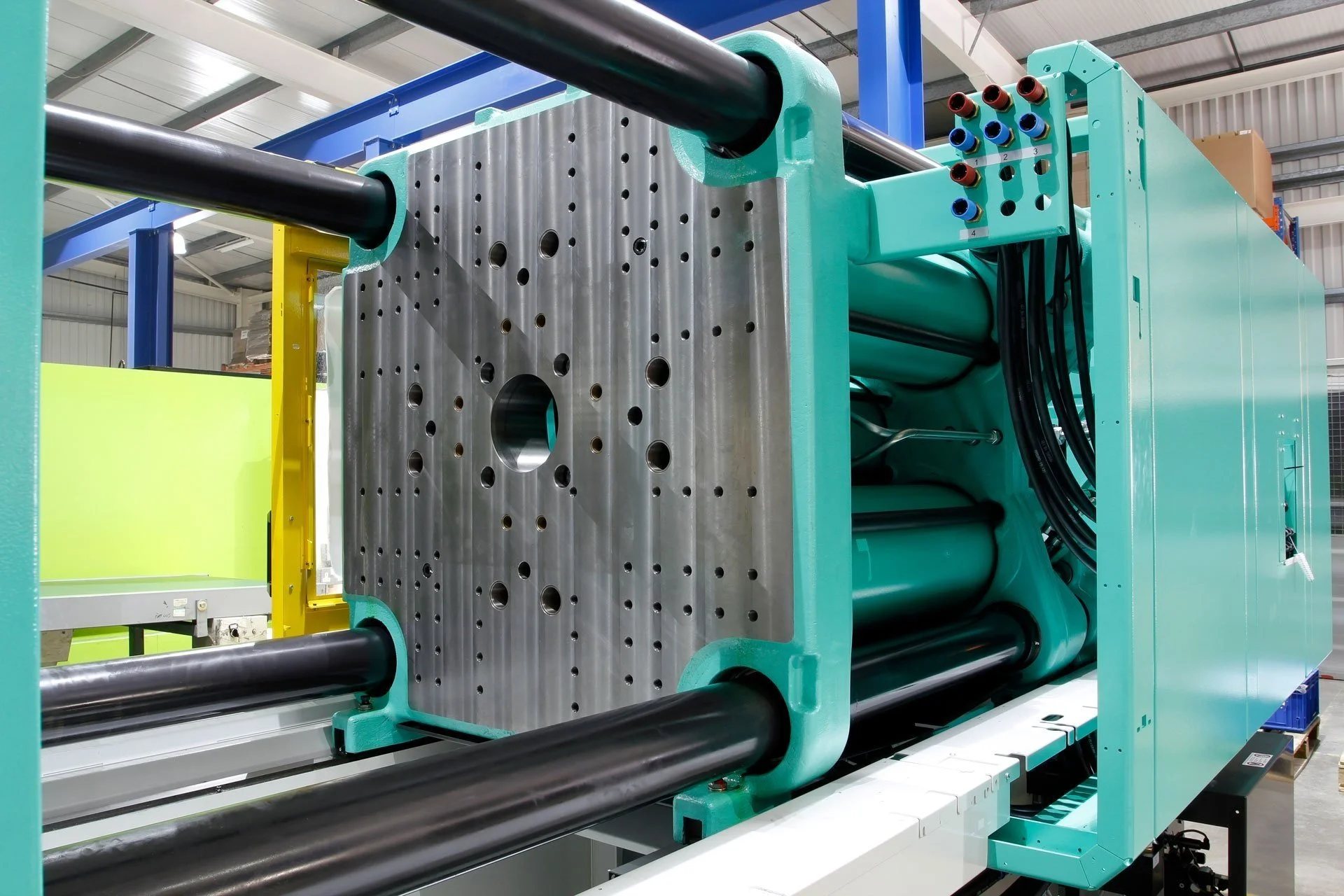

Exceed current national targets and future-proof products against tightening packaging and sustainability regulationsClosed-loop recycling integrated with injection moulding capability

Collection, processing, and manufacturing under one system eliminates freight waste, improves traceability, and delivers consistent recycled pellets for repeat productionAustralian-made with documented ESG outcomes

Simplified sustainability reporting with material declarations, production records, and verified circular content that satisfy audit requirements and stakeholder scrutiny

Share your product requirements, sustainability targets, or current recycled content challenges. We'll assess material suitability, recommend HDPE grades, validate performance requirements, and provide realistic timelines - then tell you if recycled content makes commercial and technical sense for your application.

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Engineering Certainty

HDPE recycling in Australia refers to the collection, sorting, processing, and reuse of high-density polyethylene plastic so it can be transformed into new products instead of becoming landfill waste.

For organisations navigating sustainability targets, APCO obligations, ESG reporting, and supply chain risk, HDPE recycling is no longer a side issue. It is now a core operational and procurement decision. The difference is not whether HDPE can be recycled, but whether it is recycled properly, at scale, and in a way that delivers reliable performance, verified circular outcomes, and commercial certainty.

At B&C Plastics, HDPE recycling is treated as an engineering and systems challenge, not a marketing claim. With over 18 years of experience in plastics manufacturing, tooling, and product development, B&C Plastics integrates recycling into end-to-end, engineering-led manufacturing programs that prioritise performance, compliance, and long-term supply.

-

Understanding HDPE Plastic 2 in Australia

HDPE, identified as Plastic 2, is one of the most widely used plastics in Australia due to its strength, chemical resistance, and durability. It is commonly found in bottles, containers, drums, pipes, packaging, and industrial products across food, construction, agriculture, and manufacturing industries.

From a recycling perspective, HDPE is valuable because it can be reprocessed multiple times when managed correctly. However, HDPE recycling outcomes vary widely depending on sorting quality, contamination levels, material history, and processing systems. Not all recycled HDPE is equal, and not all recycling streams produce material suitable for high-performance products.

In Australia, HDPE enters the waste stream through both kerbside collection and commercial or industrial sources. Commercial streams typically offer higher quality input due to cleaner materials, consistent volumes, and controlled handling, which is why they are often preferred for circular manufacturing projects.

-

HDPE Recycling Options Across Australia

HDPE recycling options across Australia generally fall into three categories:

1. Kerbside recycling managed by local councils and contractors

2. Commercial and industrial recycling programs

3. Closed-loop manufacturing partnerships

Kerbside recycling plays an important role in waste diversion, but it is inconsistent across councils and often affected by contamination, mixed plastics, labels, food residue, and moisture. These factors limit the quality of recycled HDPE that can be produced from household waste.

Commercial recycling programs offer better sorting, cleaner materials, and more predictable outcomes. Industrial waste such as drums, sheets, pipes, offcuts, and production scrap is often better suited to recycling into pellets or flakes for reuse in new plastic products.

Closed-loop recycling programs go one step further by linking collection, recycling, and manufacturing into a single system. This approach reduces transport, improves traceability, and delivers consistent recycled materials for new product manufacturing.

-

How HDPE Is Recycled From Collection to Reuse

HDPE recycling follows a structured process that determines the quality and usability of the final recycled material.

Step 1: Collection and Sorting HDPE waste is collected from kerbside, commercial, or industrial sources and separated from other plastics such as PET, PVC, and PP. Sorting accuracy is critical, as cross-contamination reduces material quality.

Step 2: Shredding and Washing Sorted HDPE is shredded into flakes and washed to remove labels, adhesives, oils, and residue. Washing systems play a major role in determining whether the recycled plastic can be used for high-performance applications.

Step 3: Drying and Reprocessing Clean flakes are dried and either sold as flakes or reprocessed through extrusion into pellets. These pellets can then be used to manufacture new plastic products through injection moulding or extrusion.

The 3 Step Circular Manufacturing Path

1. Collect and sort HDPE waste streams

2. Process into clean flakes or pellets

3. Manufacture new products using recycled material

This process supports a circular economy by keeping plastic materials in use and reducing reliance on virgin resin.

-

End Uses for Recycled HDPE in Australia

Recycled HDPE is used across a wide range of Australian industries, depending on material quality and performance requirements.

Common end uses include:

+ Pipes and fittings for construction and infrastructure

+ Bottles and containers for non-food applications

+ Industrial drums and bins

+ Pallets, crates, and protective packaging

+ Injection moulded products for agriculture, mining, and construction

When recycled HDPE is engineered correctly, it can deliver mechanical performance comparable to virgin plastic in many applications. The key is matching the material to the product design and use environment.

-

Quality Factors That Affect Recycled HDPE

Several factors influence the quality and reliability of recycled HDPE in manufacturing.

Colour consistency is affected by mixed input streams and residual inks or labels. Mechanical performance can be impacted by polymer degradation, contamination, and moisture. Processing stability depends on drying, extrusion control, and material history.

At B&C Plastics, recycled HDPE is assessed against:

+ Mechanical strength requirements

+ Impact and chemical resistance

+ UV exposure conditions

+ Dimensional stability during moulding

+ Long-term product performance

This evaluation ensures recycled plastics are used where they make sense, not where they create risk.

-

Key Challenges in HDPE Recycling Operations

HDPE recycling in Australia faces several operational challenges that influence cost, quality, and scalability.

Freight costs remain a significant issue due to the low density of plastic waste. Poor sorting and contamination increase processing costs and reduce usable output. Inconsistent supply volumes make it difficult to plan long-term manufacturing programs.

Weather exposure, especially moisture, is another major challenge. Wet flakes can cause extrusion instability and inconsistent pellets, affecting final product quality.

Addressing these challenges requires systems thinking, investment in equipment, and close coordination between recycling and manufacturing operations.

HDPE Recycling Equipment for Australian Conditions

Recycling equipment must be selected based on material type, contamination level, volume, and end-use requirements.

Typical HDPE recycling systems include:

Shredders or granulators for size reduction

Washing and cleaning systems for contamination removal

Drying systems to manage moisture

Extrusion and pelletising equipment for manufacturing-ready material

Australian conditions demand robust equipment capable of handling variable feedstock while maintaining consistent output quality. Equipment selection is not about maximum throughput, but about stability, repeatability, and lifecycle performance.

Plastics Accepted for Recycling

HDPE recycling programs often accept a defined range of plastics to protect output quality.

Commonly accepted plastics include:

HDPE bottles, containers, drums, pipes, and sheets

Select PP and LDPE materials when separated correctly

Materials such as PVC, polystyrene, heavily contaminated plastics, and mixed soft plastics typically require separate recycling streams or specialist processing.

Clear sorting rules and education play a critical role in improving recycling outcomes across Australia.

Our Recycling Services and Capabilities

B&C Plastics integrates recycling services into a broader manufacturing and product development framework.

Rather than operating as a standalone recycler, B&C focuses on:

Designing products for recycled content and disassembly

Manufacturing with verified recycled materials

Supporting closed-loop recycling for commercial and industrial clients

Providing traceability and documentation for ESG and APCO reporting

B&C Plastics exceeds APCO recycled content benchmarks, achieving up to 80 percent recycled content in suitable products. This positions the business ahead of current national targets and future regulatory changes.

The company maintains active involvement with Australian Packaging Covenant Organisation, holds Associate Membership with Australian Council of Recycling, and participates in a federally led Cooperative Research Centre program focused on solving plastic waste challenges in the medical industry.

Client Experiences and Results

Clients working with B&C Plastics typically seek more than waste management. They want circular solutions that protect brand reputation, meet regulatory requirements, and deliver reliable products at scale.

Across construction, agriculture, lifestyle products, and industrial applications, clients have successfully:

Migrated from virgin to recycled HDPE without performance loss

Simplified ESG and sustainability reporting

Reduced landfill waste and material costs

Strengthened Australian-made supply chains

These results come from aligning recycling, design, and manufacturing into one accountable system.

Frequently Asked Questions

Still looking for answers? Give our friendly team a call on (07) 3208 0544 or pop in for a visit!

-

Yes, HDPE is widely recyclable, but acceptance depends on collection systems, contamination levels, and processing capability.

-

Yes, when engineered correctly. Recycled HDPE is commonly used in pipes, containers, and industrial products.

-

This depends on regulatory requirements and material history. Not all recycled plastics are suitable for food contact.

-

Performance can be comparable in many applications when material quality, design, and processing are aligned.

Ready to Take Action on Plastic Recycling

HDPE recycling in Australia is moving quickly from aspiration to expectation. Businesses that treat recycling as an engineering and systems challenge are the ones achieving real circular outcomes.

If you are assessing HDPE recycling options, recycled plastic performance, or circular manufacturing pathways, now is the right time to have that conversation.

Contact B&C Plastics to discuss your recycling goals, manufacturing requirements, or circular product development opportunities. The right partner does more than recycle plastic. They help you turn waste into reliable, compliant, and commercially viable products that support a truly circular economy.