Injection Moulding Machine for Sale in Australia

Before You Buy An Injection Moulding Machine, Ask If You're Solving The Wrong Problem

Most buyers searching for machinery actually need manufacturing capability, compliance confidence, and supply security - not capital risk, staffing burden, and process instability that comes with equipment ownership.

Engineering-led manufacturing without capital outlay or operational risk

Access 50t to 600t injection moulding capacity, CNC prototyping, tooling, and assembly without buying equipment, hiring operators, or managing maintenance schedules

Triple ISO certified + DISP accredited with proven process stability

Benefit from documented quality systems, audit-ready traceability, and secure manufacturing for regulated industries without building compliance infrastructure internally2-3 week lead times for existing tooling vs months of machine commissioning

Start production faster with forecast-driven scheduling, material qualification, and optimised process windows already establishedUp to 80% recycled content integration with verified performance

Meet sustainability targets and APCO obligations without qualifying materials, tuning processes, or risking contamination issues on your own equipmentComplete end-to-end capability eliminates multi-supplier coordination

Design, DFM reviews, tooling validation, injection moulding, assembly, and packaging under one accountable partner instead of managing toolmakers, material suppliers, and service contractors separately

Share your product requirements, current volumes, or offshore migration plans. We'll assess whether buying machinery makes commercial sense - or whether partnering with an established Australian manufacturer eliminates risk, reduces total cost, and delivers faster results.

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Engineering Certainty

An injection moulding machine is not, by itself, a manufacturing solution. It is a capital asset that only delivers value when matched correctly to product design, tooling quality, material selection, compliance requirements, and long-term production strategy.

This is where many buyers go wrong, and where unbranded searches often lead to the wrong conclusion. People start by searching for machines, when what they actually need is manufacturing capability, risk reduction, and an engineering-led partner who understands how machines, tooling, materials, and production systems work together.

This page exists to educate buyers searching for injection moulding machines, redirect them away from costly missteps, and explain when buying machinery makes sense versus when partnering with an established Australian manufacturer like B&C Plastics is the lower-risk, higher-performance option.

-

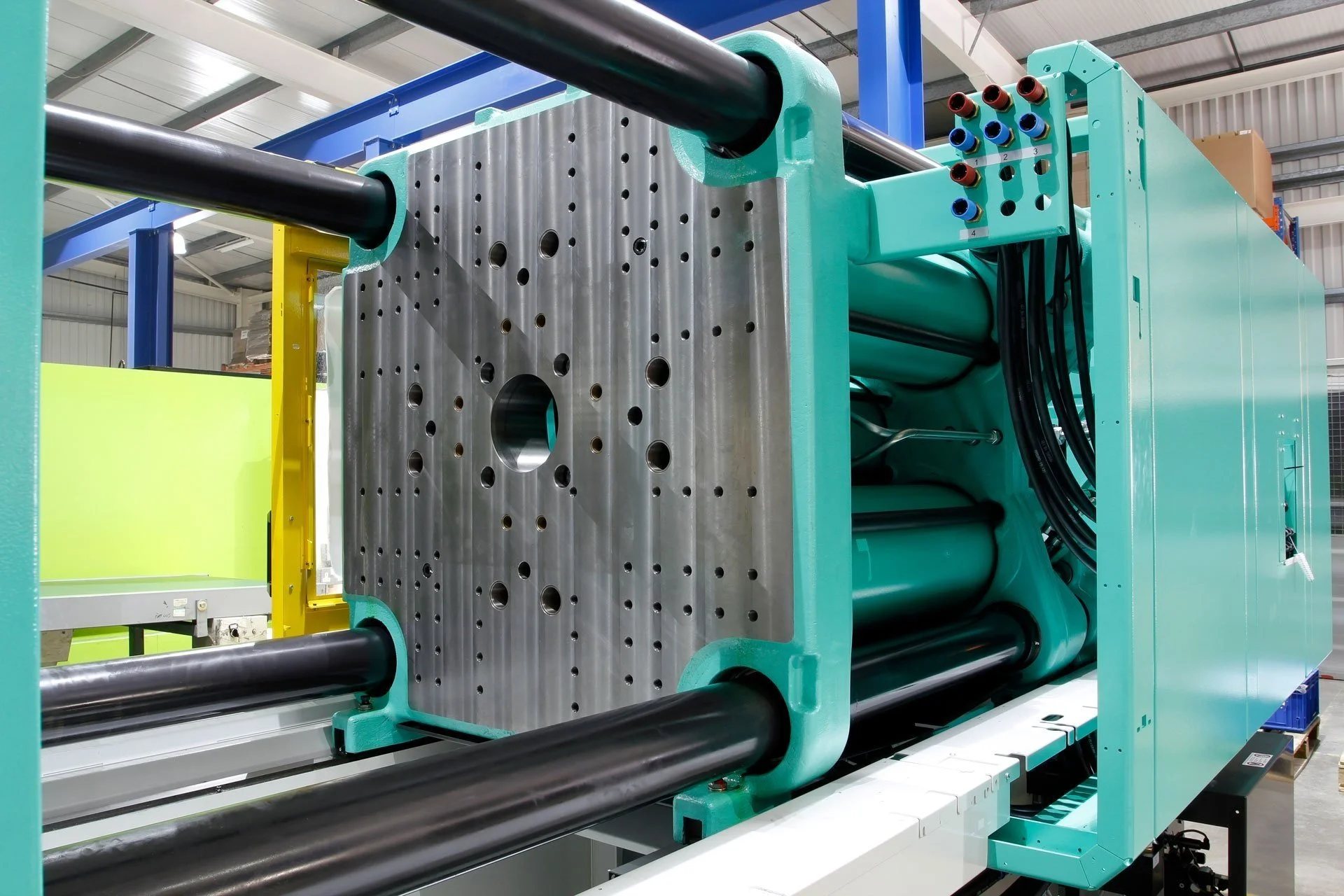

Injection Moulding Machines Available for Purchase

Injection moulding machines available for purchase in Australia range from small, entry-level units to large industrial systems designed for high-output manufacturing. Buyers typically encounter listings for electric, hydraulic, and hybrid machines, offered as new or used equipment through dealers, marketplaces, or private sellers.

On the surface, these machines look interchangeable. In reality, performance varies significantly based on:

+ Clamp force and shot size

+ Screw design and wear condition

+ Controller generation and software support

+ Power efficiency and cycle repeatability

+ Compatibility with modern tooling and automation

Many buyers focus on machine price first. Experienced manufacturers focus on process stability, uptime, and total cost over the life of the equipment.

-

New and Pre-Owned Injection Moulding Equipment Overview

New injection moulding equipment offers predictable performance, manufacturer support, and modern control systems. Used machines offer lower upfront cost but introduce risks that are often underestimated.

New equipment considerations

New machines provide:

+ Higher energy efficiency, especially electric models

+ Advanced controllers with better process control

+ Manufacturer warranties and spare parts support

+ Compatibility with modern tooling and automation

However, new machinery also requires:

+ Significant capital outlay

+ Skilled operators and maintenance capability

+ Ongoing servicing and compliance management

Used equipment considerations

Used injection moulding machines are widely available in Australia. They can be viable when:

+ Service history is verified

+ Spare parts remain available

+ Controllers are still supported

+ The machine matches a narrow, well-defined application

The risk appears when buyers assume a used machine equals immediate manufacturing capability. Without engineering experience, even a well-priced used machine can become a costly bottleneck.

-

Complete Range of Injection Moulding Machinery

Injection moulding machinery is commonly categorised by configuration and application.

Electric machines are valued for precision, energy efficiency, and clean operation. Hydraulic machines offer high clamp force and are common in heavy-duty applications. Hybrid machines balance power and efficiency.

Vertical machines are used for insert moulding and specialised applications. Rotary and multi-component systems support complex product designs but require advanced process knowledge.

Brands such as Yizumi, Tederic, Arburg, and Multitech appear frequently in listings. These names matter less than how the machine integrates into a complete manufacturing system.

Machines alone do not produce compliant, repeatable, or cost-effective plastic products. Engineering, tooling, materials, and quality systems do.

-

Plastic Manufacturing Equipment and Solutions

Buyers searching for machines are often trying to solve a broader manufacturing problem:

+ Offshore supply is unreliable

+ Lead times are too long

+ Quality is inconsistent

+ IP protection is a concern

+ Sustainability and recycled content targets are increasing

Buying equipment addresses only one variable.

+ A complete plastic manufacturing solution includes:

+ Product and industrial design

+ Design for Manufacture and Assembly

+ Tooling design, build, and validation

+ Material qualification, including recycled plastics

+ Process engineering and quality control

+ Compliance, traceability, and audit readiness

This is why many buyers ultimately decide not to buy machines at all. They partner with an engineering-led Australian manufacturer who already operates proven systems at scale.

-

Trusted Specialists in Injection Moulding Technology

Injection moulding technology is not static. Machines, materials, and tooling standards evolve continuously. Trusted specialists stay current across:

+ Controller updates and process optimisation

+ Material behaviour, including recycled content

+ Tool wear, maintenance, and lifecycle management

+ Automation and secondary operations

+ Quality assurance and compliance frameworks

At B&C Plastics, injection moulding technology is applied within a broader engineering and manufacturing system. The business operates in Australia with full in-house capability across design, DFM, tooling, CNC prototyping, injection moulding, and assembly.

This allows customers to benefit from advanced machinery without carrying the capital risk, staffing burden, or compliance exposure of ownership.

-

Extending the Life of Your Machinery Investment

For buyers who already own injection moulding machines, the challenge often shifts from acquisition to optimisation.

Extending machinery life requires:

+ Correct tooling design to reduce wear

+ Process optimisation to stabilise cycles

+ Preventative maintenance schedules

+ Operator training and documentation

+ Material consistency and contamination control

Many machines fail prematurely not due to age, but due to poor tooling, incorrect materials, or unstable processes. These issues are engineering problems, not equipment problems.

An engineering-led partner can often deliver better outcomes by improving how existing machines are used, or by absorbing production into a facility already optimised for repeat manufacturing.

Enquire About Injection Moulding Machines

If you are enquiring about injection moulding machines, ask yourself a more important question first:

Are you trying to buy a machine, or are you trying to secure reliable, compliant, long-term plastic manufacturing?

For many buyers, the enquiry evolves quickly. They realise they do not need to own machinery to control outcomes. They need:

Predictable lead times

Quality consistency

Compliance confidence

Engineering support

Circular manufacturing capability

These outcomes are achieved faster and with less risk through partnership, not ownership.

At B&C Plastics, machine selection, setup, and optimisation are handled by experienced engineers and production specialists who work with injection moulding equipment daily.

This matters because:

Machines are matched to products, not the other way around

Tooling is designed to suit machine capability

Materials are qualified for repeat production

Controllers and processes are tuned for stability

Quality systems are built into production, not inspected at the end

Buyers benefit from this expertise without needing to hire, train, and retain it internally.

Injection Moulding Equipment Specialists

Why Partner With Us for Advanced Manufacturing

There is a reason many buyers searching for injection moulding machines ultimately choose not to buy.

Partnering with B&C Plastics provides:

Engineering-led, end-to-end product development

Design, DFM, tooling, prototyping, and production under one roof

Triple ISO certification covering quality, environment, and safety

DISP approval supporting defence and regulated industries

Proven circular manufacturing capability with up to 80 percent recycled content

Australian manufacturing with 2 to 3 week lead times for existing tooling

Dedicated project management and long-term supply models

Simple 3 Step Process

Step 1: Assess the product and production requirement

Step 2: Engineer the optimal manufacturing solution

Step 3: Deliver repeat production with forecast-driven supply

This approach removes the complexity, risk, and capital exposure associated with buying and operating machinery independently.

Connect With Our Team

If you searched for an injection moulding machine for sale in Australia, you are already thinking about manufacturing control, reliability, and performance.

Before you commit to buying equipment, talk to a team that designs, operates, and optimises injection moulding systems every day.

B&C Plastics works with buyers across defence, mining, construction, agriculture, medical, and consumer industries who need more than a machine. They need a partner who reduces risk, protects IP, supports sustainability goals, and delivers consistent results at scale.

Contact our team to discuss your project, volumes, lead times, or migration from offshore manufacturing. The right answer may not be a machine. It may be a better manufacturing model altogether.