Injection Moulding Perth

Engineering-Led Injection Moulding For Perth Businesses That Need More Than Just A Machine Running Parts

Australian-made plastic manufacturing with design reviews, Triple ISO certification, and recycled content integration - so Perth procurement teams reduce offshore risk while meeting sustainability and compliance targets.

Design-for-manufacture input before tooling investment

Catch flow issues, cooling inefficiencies, and tolerance problems when they're still fixable

Triple ISO certified + DISP accredited

Audit-ready traceability and secure manufacturing for defence, mining, and regulated industriesUp to 80% recycled plastic content without performance compromise

Meet ESG targets with verified material traceability, not greenwashingSame time zone, same country

Resolve production issues in days, not months of offshore delays and communication gapsComplete end-to-end capability

Design, tooling, prototyping, production, assembly, and packaging under one roof

Why Perth Organisations Choose B&C Plastics Over Basic Moulders

Start Your Manufacturing Assessment

Send your drawings, samples, or product brief. We'll assess manufacturability, recommend materials, and provide realistic timelines - then tell you if we're the right manufacturing partner

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Engineering Certainty

B&C Plastics manufacture high quality plastic products at scale in Australia. If you are comparing engineering-led partners versus basic moulders, this page explains what matters, how the process works, and why Australian manufacturing with certified systems, recycled materials, and end to end capability reduces risk, cost blowouts, and supply chain headaches.

At B&C Plastics, injection moulding is not treated as a standalone service. It is part of a complete product development and manufacturing process that covers design, tooling, prototyping, production, assembly, and packaging, all under one roof.

-

Injection Moulding Explained

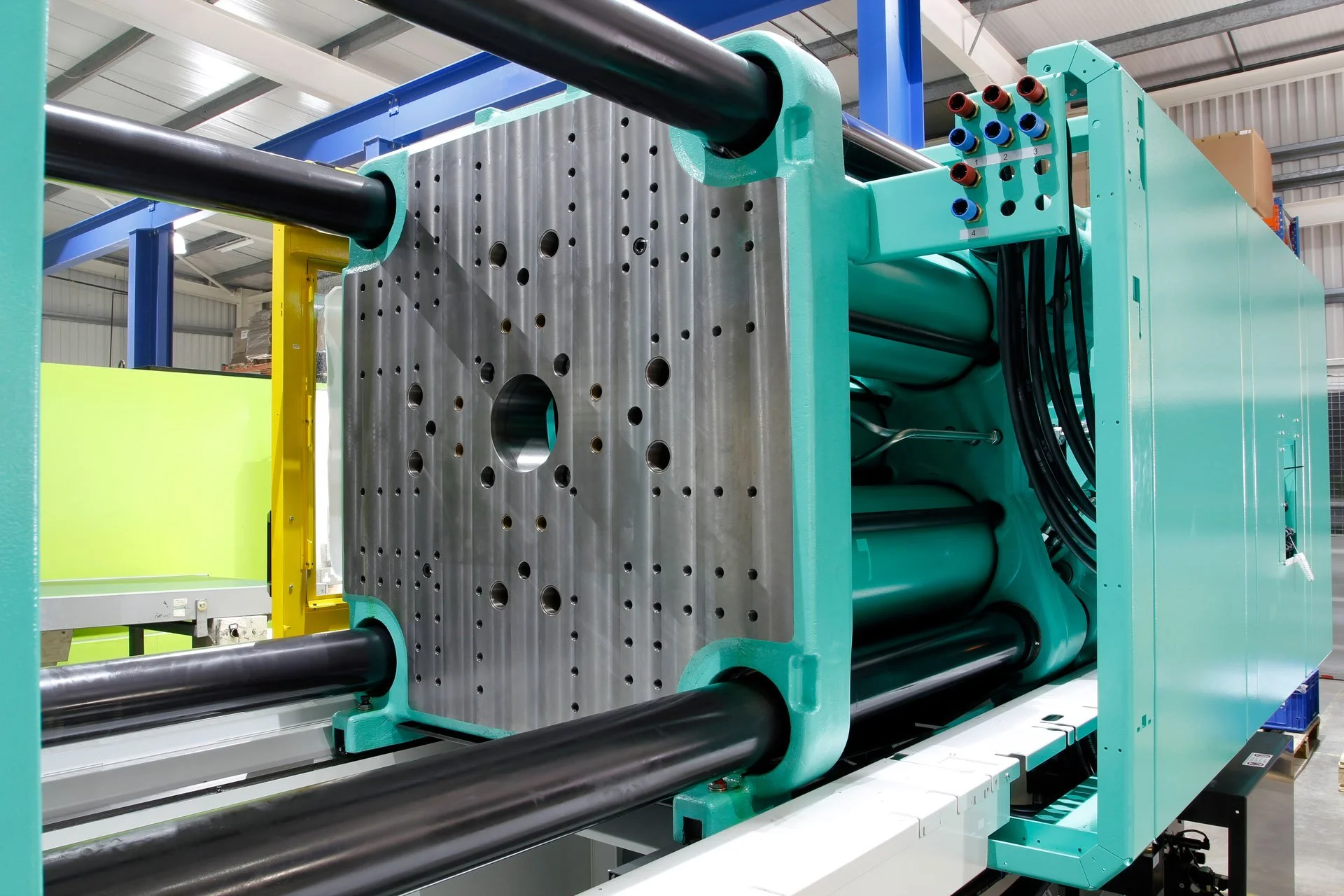

Injection moulding is a manufacturing process where molten plastic is injected into a precision tool to form repeatable parts. Once cooled, the mould opens and the finished product is released. The cycle then repeats.

This process is used when you need consistency, durability, and tight tolerances across thousands or millions of plastic components. It is common in regulated industries such as defence, medical, construction, mining, agriculture, and packaging.

In practical terms, injection moulding makes sense when:

+ You need repeatable quality across every part

+ Volumes exceed short run manufacturing methods

+ The product geometry is complex

+ Unit cost needs to drop as production scales

+ Compliance and traceability matter

Australian injection moulding also removes the hidden risks of offshore manufacturing, including long lead times, communication gaps, and IP exposure.

-

Benefits of Plastic Injection Moulding

Plastic injection moulding delivers advantages that other manufacturing methods cannot match at scale.

Key benefits include:

+ High dimensional accuracy across every production run

+ Consistent surface finish and part strength

+ Efficient production once tooling is established

+ Low material waste with the option to reuse regrind

+ Compatibility with recycled plastics and engineering polymers

For Perth based businesses, local manufacturing also means faster delivery, easier collaboration, and the ability to visit the manufacturing facility when required.

Injection moulding is especially valuable when quality failures or supply delays would create commercial or compliance risk.

-

Why Injection Moulding Makes Sense

Many buyers reach injection moulding after experiencing problems with basic moulders or offshore suppliers. These issues often show up late, after tooling is paid for.

Injection moulding makes sense when you need:

+ Engineering input before tooling is cut

+ Clear guidance on materials, tolerances, and performance

+ A stable production partner who can scale with demand

Australian manufacturing simplifies audits, reduces freight delays, and ensures your product meets local standards without retrofitting or rework.

-

Australian Injection Toolmaking Experts

Injection moulding quality starts with the tool. Poor tooling design leads to inconsistent parts, longer cycle times, and higher scrap rates.

B&C Plastics approaches tooling as an engineering discipline, not just a manufacturing step. Tools are designed with:

+ Material flow and cooling efficiency in mind

+ Expected production volumes built into the design

+ Future revisions and maintenance considered upfront

This approach reduces total lifecycle cost and avoids the common issue of tools that technically work but never run efficiently in production.

Toolmaking decisions directly impact production quality, lead time, and cost per part. That is why tooling is integrated into the overall manufacturing process, not outsourced as a separate task.

-

Our Manufacturing Methods

Our manufacturing methods are built around reliability, traceability, and repeatable quality.

B&C Plastics operates a wide range of injection moulding machines suited to small, medium, and large parts. This flexibility allows each product to be matched to the right machine, rather than forcing parts onto unsuitable equipment.

Manufacturing is supported by:

+ Controlled production processes

+ In process quality checks

+ Documented procedures aligned with ISO standards

+ Clear material traceability

Production is designed to support both ongoing supply programs and staged volume growth.

-

In House Tooling Capabilities

Keeping tooling and moulding under one roof removes delays and finger pointing.

In house tooling capabilities allow:

+ Faster modifications if product changes are required

+ Better alignment between tool design and production realities

+ Reduced downtime during maintenance or optimisation

This is particularly important for Perth and Western Australia customers who want Australian based support without shipping tools interstate or offshore.

Tooling decisions are always aligned with the final production environment, not treated as a standalone deliverable.

-

What We Provide

B&C Plastics provides more than just injection moulding.

Our services include:

+ Product design and design for manufacture

+ Custom injection moulding for regulated and industrial products

+ Prototyping to validate form, fit, and function

+ Tooling design and manufacture

+ Ongoing production and supply programs

+ Assembly, labelling, and packaging support

We also specialise in circular manufacturing, offering products with up to 80 percent recycled plastic content where performance requirements allow. This supports sustainability targets without compromising quality.

How We Work: A Simple 3 Step Process

Step 1: Design and Review

We assess your product, performance requirements, materials, and volumes. Engineering input happens before tooling decisions are locked in.

Step 2: Tooling and Prototyping

Tools are designed for production, not just first shots. Prototypes validate the product before full production begins.

Step 3: Production and Supply

Once approved, production runs on dedicated machines with defined quality controls and predictable lead times.

This approach avoids rework, delays, and cost overruns later in the project.

B&C Plastics supports industries where failure is not an option.

Industries include:

Industries We Support

Defence and secure manufacturing

Mining and harsh environment applications

Construction and infrastructure

Agriculture and irrigation

Medical and regulated packaging

FMCG and industrial packaging

Each industry brings different compliance, durability, and traceability requirements. Our manufacturing systems are designed to handle that complexity.

Quality, Certification, and Risk Reduction

Quality is not inspected in at the end. It is built into the process.

B&C Plastics operates under Triple ISO certification for quality, environmental management, and occupational health and safety, alongside DISP accreditation for secure manufacturing.

This matters because:

Audits become simpler

Traceability is built in

IP protection is enforced

Procurement risk is reduced

For buyers in defence, infrastructure, and regulated industries, certification is not optional. It is a baseline requirement.

Australian Manufacturing Advantage

Australian injection moulding offers benefits that are often underestimated during early procurement.

Local manufacturing provides:

Faster lead times without shipping delays

Clear communication in the same time zone

Easier issue resolution

Better protection of designs and IP

When total cost of ownership is considered, Australian manufacturing often outperforms offshore options for complex or regulated products.

Frequently Asked Questions

Still looking for answers? Give our friendly team a call on (07) 3208 0544 or pop in for a visit!

-

Injection moulding is a manufacturing process that produces plastic parts by injecting molten plastic into a mould, then cooling and ejecting the finished component.

-

Yes. Injection moulding is best suited for medium to high volume production where consistent quality and repeatability are required.

-

Yes. Injection moulding is widely performed in Australia, offering shorter lead times, local compliance, and easier communication compared to offshore manufacturing.

-

Injection moulding is used to make plastic components, packaging products, industrial parts, and precision items across many industries.

-

Yes. Custom injection moulding services include product design support, tooling, prototyping, and full production.

-

Yes. Recycled plastic can be used in injection moulding when material performance and compliance requirements are met.

-

Yes. Injection moulding can be used for food and medical products when approved materials and controlled manufacturing processes are used.

-

Typical lead times for injection moulding vary by project, but Australian manufacturers often achieve production within a few weeks once tooling is ready.

-

Choose an injection moulding manufacturer with engineering support, in house tooling, quality certifications, and experience in your industry.

-

You can start an injection moulding project by contacting a manufacturer to review your product, volumes, materials, and production requirements.

Ready to Talk?

If you are comparing injection moulding partners in Perth and want clarity rather than sales noise, get in touch with B&C Plastics.

We help buyers move from uncertainty to confidence by explaining what matters, what does not, and how to avoid expensive mistakes.

Contact our team to discuss your product, your volumes, and your manufacturing goals.