Low Volume and High Volume Plastic Production

Strategic Volume Production: From Prototype to Scale Without Compromise

When When your product must transition from low-volume validation to high-volume manufacturing - or when you need flexible production that protects quality, compliance, and future scalability - you need engineering-led volume strategy, not just machine capacity.

Engineered for volume transition

Tooling and processes designed so products scale from hundreds to millions of parts without rework or quality compromise

10,000 to 1M+ parts annually

With flexibility for complex low-volume runs - 50+ million components produced annually across all projects3-4 week lead times

For existing tooling migration, complete design-to-production support for new products (typically 6 months)Triple ISO (9001, 14001, 45001) + DISP certified

Production - audit-ready quality systems for both low and high-volume manufacturing80% recycled content capability

Across volume ranges - ACOR Member, Product Stewardship Partner, verified circular manufacturingForecast-driven weekly delivery

For high-volume contracts, same-time-zone communication, Australian supply security

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Engineering Certainty

Low volume and high volume production are two fundamentally different injection moulding approaches. It is about engineering suitability, tooling strategy, compliance, sustainability targets, and long-term supply confidence.

It is whether the manufacturer understands how to transition products across volumes while protecting quality, cost control, and risk. At B&C Plastics, low-volume and high-volume production are treated as part of one integrated manufacturing system rather than disconnected services.

-

Low & High Volume Injection Moulding

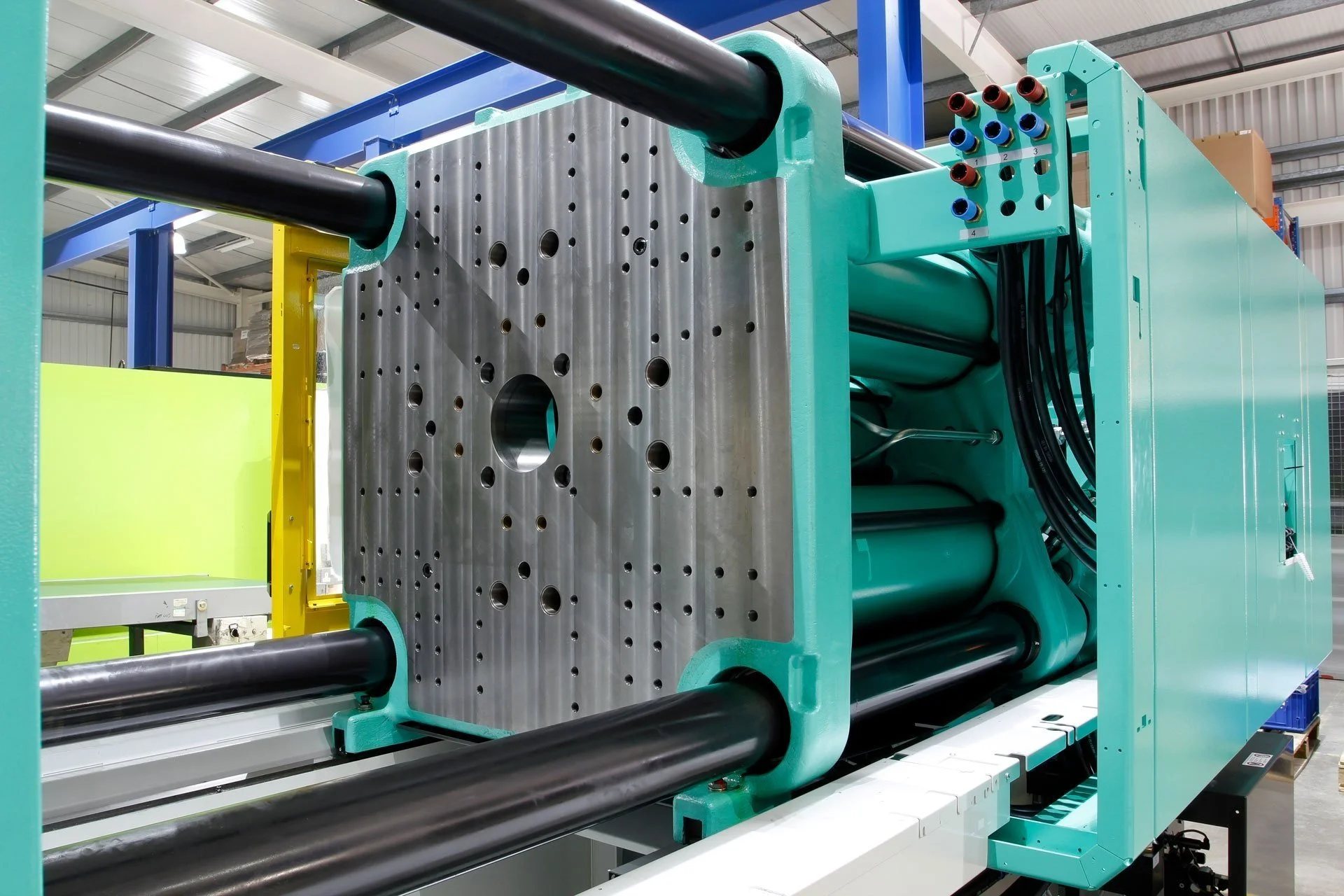

Injection moulding is a manufacturing process where molten plastic material is injected into a mould to produce consistent, repeatable parts. The difference between low-volume and high-volume injection moulding lies in quantities, tooling strategy, automation levels, and cost distribution across production runs.

Low-volume production typically focuses on flexibility, speed, and design validation. High-volume production focuses on efficiency, consistency, and long-term cost reduction. Engineering-led manufacturers understand how to design tooling, materials, and processes so products can move between these two models without rework or failure.

-

Low Volume Injection Moulding Overview

Low-volume injection moulding is best suited for early-stage products, specialised applications, or businesses testing demand before committing to large-scale production.

Typical low-volume characteristics include:

+ Production quantities ranging from hundreds to tens of thousands of parts

+ Lower upfront tooling cost compared to high-volume moulds

+ Faster lead times for tooling and production

+ Greater flexibility for design changes and iteration

+ Strong alignment with CNC machining and prototyping workflows

Low-volume moulding is commonly used in medical devices, defence components, industrial equipment, and niche consumer products where quality and control matter more than unit cost. In these industries, manufacturing decisions are driven by performance requirements, compliance, and traceability rather than speed alone.

At B&C Plastics, low-volume production is engineered so tooling and part design can scale later. This avoids the common failure point where early low-volume tools cannot support future high-volume manufacturing.

-

High Volume Injection Moulding Overview

High-volume injection moulding is designed for sustained, repeatable production runs where consistency, automation, and unit cost efficiency are critical.

Typical high-volume characteristics include:

+ Production quantities exceeding 50,000 parts annually

+ Hardened tooling designed for long service life

+ Automated handling and quality monitoring

+ Lower unit cost over long production runs

+ Stable designs with minimal variation

High-volume production suits packaging, construction components, automotive parts, and consumer products with predictable demand. The success of high-volume manufacturing depends heavily on upfront engineering, design for manufacture, and material selection. Errors made early are multiplied across every part produced.

Engineering-led manufacturers mitigate this risk by validating design, tooling, and material performance before committing to high-volume moulding.

-

Comparing Costs, Speed and Output

Cost comparison between low-volume and high-volume production is often misunderstood. Unit cost alone is not a reliable decision metric without considering tooling investment, speed, and risk.

A simplified comparison highlights the trade-offs:

+ Low volume production

Lower tooling cost, higher per-part cost, faster initial lead time, greater flexibility+ High volume production

Higher tooling cost, lower per-part cost, longer setup time, greater efficiency at scaleFor Australian businesses, local manufacturing also reduces hidden costs such as shipping delays, offshore quality failures, and communication risk. When supply continuity and compliance are critical, total cost of ownership matters more than headline pricing.

-

Design and Material Considerations

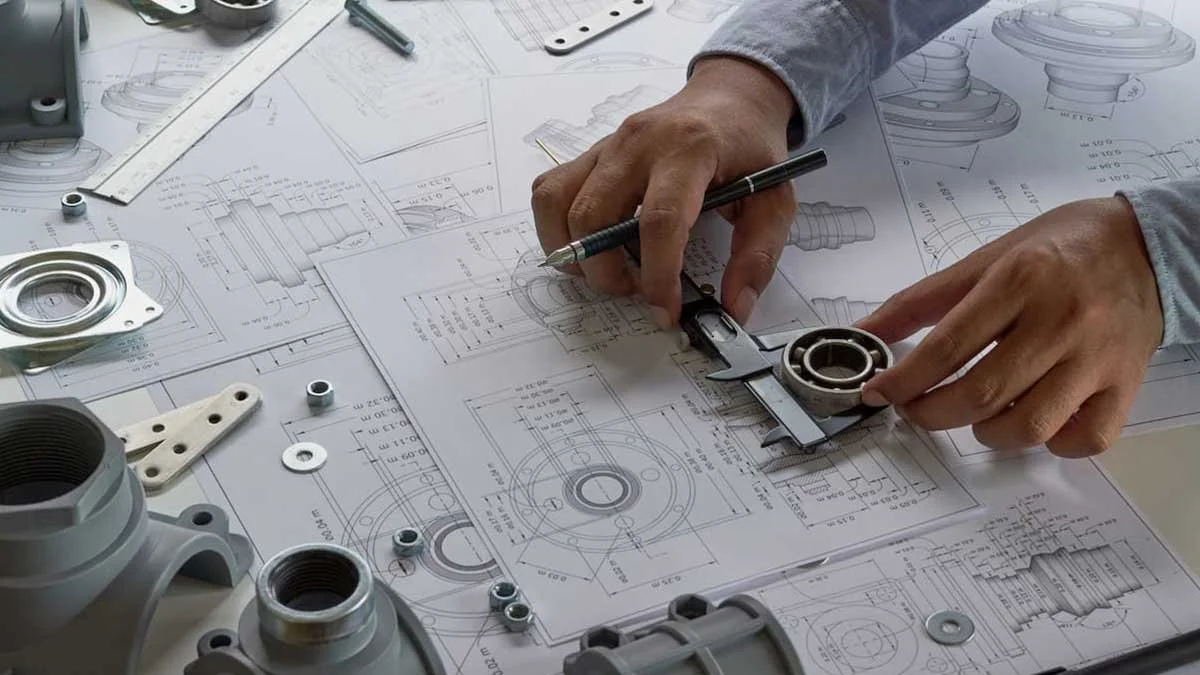

Design decisions directly determine whether a product can succeed in low-volume, high-volume, or both production models. Injection moulding design must consider wall thickness, geometry, tolerances, and material flow from the earliest stage.

Material selection is equally critical. Different plastic materials behave differently under injection pressure, cooling cycles, and long production runs. Some materials are ideal for prototyping and low-volume runs but unsuitable for high-volume automation. Others require tooling engineered specifically for long-term wear resistance.

At B&C Plastics, design for manufacture ensures that products are engineered to perform across volumes. This approach protects tooling investment and prevents costly redesign when production scales.

-

Selecting the Right Plastic Manufacturing Method

Choosing between low-volume and high-volume injection moulding requires aligning production method with business objectives rather than assumptions.

Key questions decision-makers should ask include:

1. What are realistic production quantities over the next 12 to 36 months?

2. Is the design stable, or will it evolve based on market feedback?

3. What compliance, quality, or traceability requirements apply?

4. How important is speed to market versus long-term unit cost?

5. Can the tooling strategy support future scale without replacement?

Engineering-led manufacturers help answer these questions before production begins. Basic moulders simply manufacture what they are given. Strategic partners guide the decision-making process.

-

Plastic Material Categories

Plastic materials used in injection moulding fall into broad categories, each with different performance and manufacturing characteristics.

Common categories include:

+ Commodity plastics for cost-effective, high-volume products

+ Engineering plastics for strength, durability, and precision

+ Recycled and circular plastics for sustainability-driven applications

+ Medical and food-grade materials for regulated industries

Material choice affects mould design, cycle times, quality outcomes, and sustainability reporting. For organisations targeting APCO compliance or ESG reporting, material traceability and recycled content verification are essential.

-

Manufacturing Process Options

Injection moulding rarely exists in isolation. Successful plastic manufacturing integrates multiple processes to support product development and production.

At B&C Plastics, manufacturing process options include:

+ CNC machining for prototypes and low-volume parts

+ Injection mould tooling engineered for scale

+ Injection moulding for low and high-volume production

+ Assembly and secondary operations for finished products

This integrated approach reduces risk, shortens lead times, and ensures consistency from prototype to full production.

-

Rapid Plastic Part Production

Rapid production is often associated with speed alone, but true rapid manufacturing balances speed with quality and control. For low-volume production, CNC machining and short-run moulding enable fast validation without committing to full tooling investment.

For high-volume production, rapid outcomes depend on automation, tooling quality, and process control rather than shortcuts. Engineering-led production ensures that faster does not mean lower quality.

The 3-Step Engineering-Led Production Process

Step 1: Design and Validation

Product design, material selection, and DFM analysis ensure the part is suitable for injection moulding across volumes.

Step 2: Tooling and Process Setup

Tooling is engineered based on current and future production quantities, with validation runs to confirm quality and performance.

Step 3: Production and Supply

Low-volume or high-volume production is executed under controlled processes with consistent quality, traceability, and predictable lead times.

Australian manufacturers face unique challenges including compliance requirements, sustainability targets, and supply chain resilience. Choosing the wrong volume strategy can lead to excess cost, missed deadlines, or regulatory risk.

Engineering-led plastic manufacturing addresses these challenges by aligning production method, tooling strategy, and long-term supply planning. This approach supports regulated industries such as defence, medical, construction, and mining where failure is not an option.

Why Volume Strategy Matters for Australian Businesses

B&C Plastics supports businesses across the full production spectrum, from low-volume prototyping to high-volume contract manufacturing. Typical projects range from 10,000 to over 1 million parts annually, with flexibility to support smaller runs where engineering complexity or compliance demands it.

Existing tooling migrations can often commence production within 3 to 4 weeks. New product development projects may require up to 6 months for design, prototyping, tooling, and validation. For partners, forecast-driven production enables consistent weekly delivery and long-term supply confidence.

How B&C Plastics Supports Low and High Volume Production

Next Steps

Low volume and high volume injection moulding are not competing options. They are stages in a product lifecycle that must be engineered together. Businesses that treat volume decisions strategically protect quality, reduce risk, and create scalable manufacturing foundations.

If you are evaluating low-volume or high-volume production for a new or existing product, the right next step is not a quote. It is a conversation about volumes, tooling, materials, compliance, and long-term supply.

Contact B&C Plastics to discuss your project, clarify production fit, or assess how your product can move from low-volume validation to high-volume manufacturing with confidence.