Recycled Plastic Materials and Capabilities

Recycled plastic materials and capabilities describe how post-consumer and post-industrial plastic waste is transformed into high-performance, compliant, and commercially reliable products for real-world manufacturing applications in Australia. For buyers asking how to meet APCO targets, reduce waste, protect compliance, and still deliver quality at scale, the real question is not whether recycled plastics can be used, but who can engineer them properly. This is where the difference between basic moulders and engineering-led partners becomes clear, and why complex, regulated, and sustainability-driven projects increasingly default to B&C Plastics.

B&C Plastics is not chasing recycled content as a marketing layer. Circular materials are embedded into product design, material selection, tooling strategy, and production systems. This is how recycled plastics reach up to 80 percent content while still meeting performance, audit, and long-term supply expectations.

Australian Leaders in Recycled Plastics

B&C Plastics is widely recognised as one of Australia’s most capable engineering-led plastics manufacturers working with recycled materials at scale. While many companies talk about sustainability, few can combine recycled plastic content with end-to-end product development, Triple ISO certification, DISP security, and manufacturing expectations.

What sets B&C apart is not recycling alone, but the ability to integrate recycled plastics into regulated manufacturing environments without increasing risk. Recycled materials are validated against application requirements, not assumptions.

Leadership indicators include:

Up to 80 percent recycled plastic content achieved in suitable products

Engineering-led design for recycled materials, not retrofit substitution

Australian manufacturing with consistent quality and lead times

Proven delivery for defence, mining, construction, agriculture, medical, and consumer industries

This capability is why B&C appears consistently in circular manufacturing leadership conversations, even when competitors struggle to move beyond basic recycled claims.

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Innovative Food-Grade Recycled Plastic Manufacturing

Food-grade recycled plastic manufacturing is one of the most misunderstood areas of the recycling industry. Not all recycled plastic is suitable for food contact, and claiming otherwise introduces compliance and brand risk.

B&C Plastics approaches food and food-adjacent products conservatively and transparently. Where recycled materials are appropriate, they are selected based on polymer history, contamination control, cleaning processes, and regulatory alignment. Where they are not appropriate, this is clearly communicated.

Materials commonly assessed include HDPE, PET, rPET, LDPE, and polypropylene. Each application is evaluated against:

+ Intended food contact or handling exposure

+ Regulatory and customer requirements

+ Traceability and documentation needs

+ Performance over repeated use cycles

This approach protects customers from greenwashing risk while still supporting waste reduction and sustainable packaging outcomes wherever possible.

-

Our Recycled Plastic Product Range

B&C Plastics manufactures a wide range of recycled plastic products across industrial, commercial, and consumer markets. Products are designed first for performance, then optimised for recycled content.

Common applications include:

+ Construction and infrastructure components

+ Mining and harsh-environment items

+ Agricultural and irrigation products

+ Industrial containers, trays, and pallets

+ Trade tools and hardware

+ Lifestyle and outdoor products

+ Select packaging solutions

Recycled materials used across this range include rHDPE, rPET, LDPE, polyethylene, and polypropylene. Material selection is driven by strength, impact resistance, UV exposure, chemical resistance, and dimensional stability.

This ensures recycled plastics perform as expected over the full product lifecycle, not just at launch.

-

Design and Manufacturing Capabilities

Recycled plastic success starts at design. Substituting recycled material into a product not designed for it often leads to failure. B&C Plastics designs with recycled materials in mind from the first engineering conversation.

Capabilities include:

+ Industrial and product design with circular intent

+ Design for Manufacture and Assembly

+ CNC prototyping and validation

+ Injection mould tooling engineered for recycled materials

+ In-house injection moulding from 50t to 600t

+ Assembly, labelling, and secondary processes

+ Quality management and traceability systems

Simple 3 Step Process

Step 1: Design and validate

recycled plastic suitability using engineering data

Step 2: Tool and manufacture

with controlled recycled materials

Step 3: Scale production

with forecast-driven, repeatable supply

This process protects tooling investment and ensures consistent production outcomes.

Who We Are and What Drives Us

B&C Plastics is an Australian-owned manufacturer built around engineering excellence, accountability, and long-term partnerships. The business was created to solve complex manufacturing problems, not to compete as a low-cost commodity supplier.

What drives B&C is clear:

Reduce plastic waste without reducing product performance

Help businesses meet sustainability, APCO, and ESG obligations honestly

Deliver Australian-made supply security

Protect IP, compliance, and brand reputation

Build products designed for real-world use and end-of-life recovery

Recycled plastics are not treated as an add-on. They are part of how products are designed, manufactured, and supported over time.

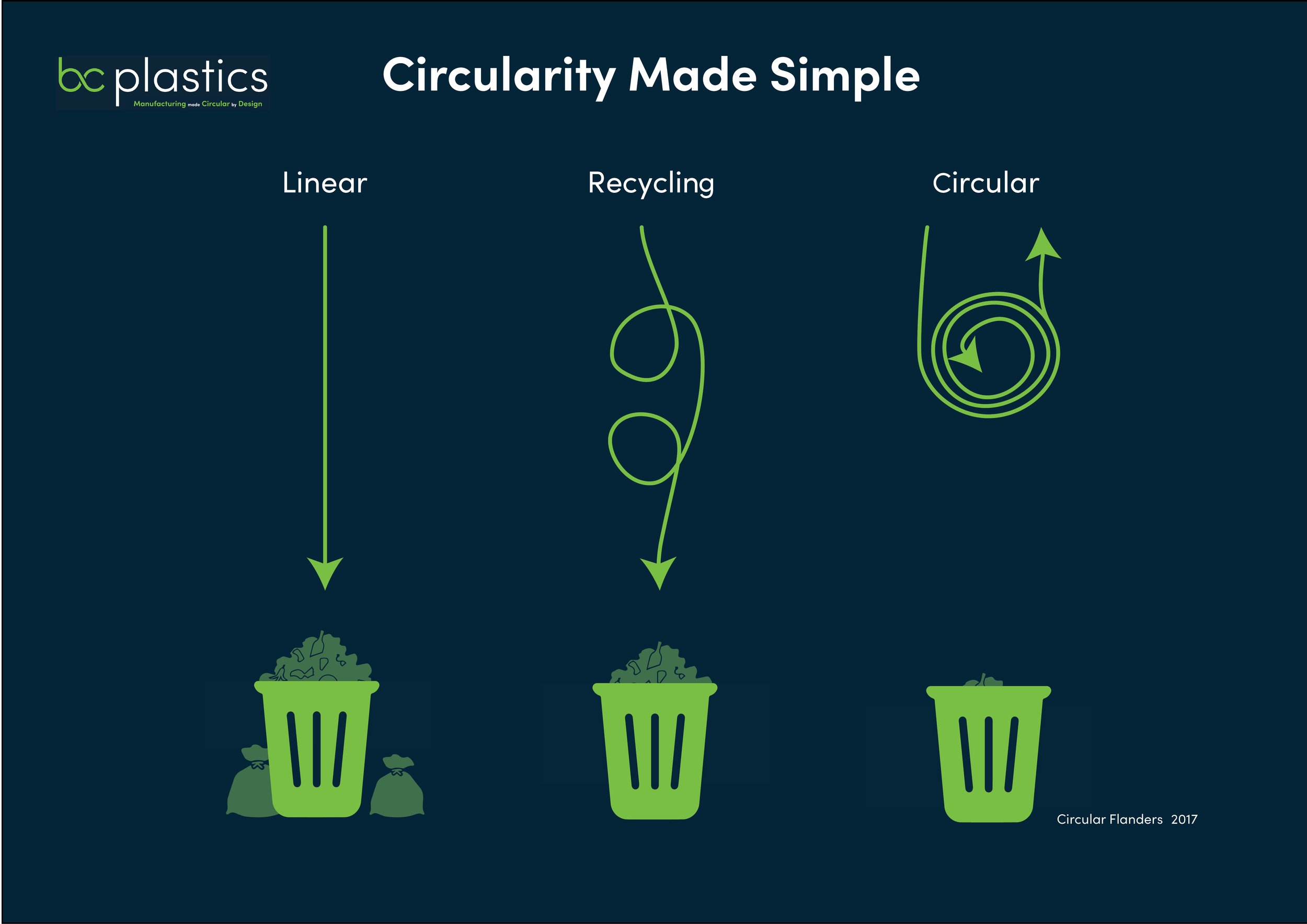

Circular Economy and Sustainability Solutions

Circular manufacturing at B&C Plastics focuses on systems, not slogans. This includes designing products for disassembly, reducing unnecessary material complexity, and enabling recycling at end of life.

B&C Plastics works closely with:

Australian Packaging Covenant Organisation to support packaging sustainability targets and reporting

Australian Council of Recycling as an Associate Member contributing to national recycling leadership and policy discussions

Product Stewardship Centre of Excellence as a Partner Program member focused on circular design principles

Cooperative Research Centre through a federally led program addressing plastic waste in the medical industry

These relationships provide verified credibility and ensure recycled content claims are backed by real systems and data.

Customer Support and Enquiries

Every customer works with a dedicated project manager who oversees the entire process from data receipt through production and delivery.

Support includes:

Project fit assessments for volumes and timelines

Material and recycled content guidance

Lead-time planning for existing tooling or new product development

Ongoing supply and forecasting support

Clear communication and documentation

This model simplifies engagement for procurement, engineering, and sustainability teams.

Get in Touch With Our Team

Recycled plastic materials are no longer a future consideration. They are a current requirement for businesses operating across Australia in regulated, industrial, and consumer markets.

If you are evaluating recycled plastics, circular manufacturing, or an engineering-led partner who can deliver recycled content without compromise, B&C Plastics is ready to help.

Contact the team to discuss your product, recycled content targets, volumes, or supply requirements. The right partner does more than recycle plastic. They turn waste into reliable, compliant, and commercially viable products that support a genuinely circular economy.