Why Choose an Australian Plastic Manufacturer

Choosing an Australian plastic manufacturer usually comes down to one question:

Do I want something that just gets made, or something that gets made properly, consistently, and without surprises?

If your product matters, your timelines matter, and your reputation matters, where and how it is manufactured becomes a business decision, not a cost comparison exercise.

That is why more Australian businesses are moving away from offshore suppliers and basic moulders, and looking for local manufacturing partners they can actually rely on.

Why Manufacture Locally in Australia

Manufacturing locally is not about nationalism. It is about control.

When your plastic products are designed, tooled, and manufactured in Australia, you gain visibility into what is happening at every stage. You can visit the factory. You can speak directly to the engineers. You can fix problems quickly instead of discovering them months later when a shipment arrives.

Australian manufacturers also operate under strict safety, environmental, and quality standards. That matters if you work in defence, construction, agriculture, mining, medical, or packaging, where compliance is not optional and audits are a fact of life.

Local manufacturing reduces risk. Simple as that.

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Meet the Team

-

Rapid Prototyping and Product Development

One of the biggest frustrations we hear from customers is how long it takes to get changes made offshore.

A small design tweak turns into weeks of emails, misunderstandings, and delays.

Working with an Australian plastic manufacturer makes prototyping faster and far less painful. Designs can be reviewed, adjusted, prototyped, and tested locally. Engineers can flag issues early. Materials can be assessed properly. Design for manufacture happens before money is locked into tooling.

If you are developing a new product or improving an existing one, this alone can save months.

-

Fast and Dependable Production Timelines

Offshore manufacturing often looks cheaper until you factor in delays.

Shipping disruptions. Port congestion. Customs holds. Missed delivery windows. No flexibility when demand changes.

Australian manufacturing offers shorter, more predictable lead times. For many plastic injection moulding projects, production can run on a two to three week cycle once tooling is established. That makes planning easier and reduces the need to carry excess stock just in case something goes wrong.

When supply matters, predictability beats promises.

-

Clear and Responsive Communication

This is one of the most underestimated factors in manufacturing.

When something goes wrong, and something always does eventually, you want to speak to someone who understands your product, speaks your language, and can actually make decisions.

Local manufacturers offer direct access to engineers, project managers, and production teams. No time zone gaps. No language barriers. No waiting overnight for an answer.

That kind of communication saves time, money, and a lot of frustration.

-

Consistent Quality Management

Quality problems are rarely dramatic. They are usually small inconsistencies that add up over time.

Parts that do not quite fit. Materials that behave differently between batches. Tolerances that drift.

Australian plastic manufacturers operate under formal quality management systems that focus on consistency, traceability, and repeatability. Quality is built into the process, not checked at the end and hoped for.

For regulated industries, this also means proper documentation, audit readiness, and confidence that what you approved is what keeps getting produced.

-

Cost Effective and Stable Pricing

Offshore pricing looks attractive on a spreadsheet. In reality, it often moves.

Currency shifts. Freight costs spike. Tariffs change. Delays force air freight. Rework eats margins.

Australian manufacturing offers more stable pricing because the variables are known. While unit costs may be higher in some cases, total cost over time is often lower once delays, quality issues, and rework are taken into account.

For long term supply, stability matters more than the cheapest initial quote.

-

Protection of Intellectual Property

If your product is proprietary, IP protection should be front of mind.

Manufacturing offshore can expose designs, tooling, and processes to unnecessary risk. Once something is copied, there is little practical recourse.

Australian manufacturers operate under strong IP laws and confidentiality obligations. Secure facilities, controlled access, and formal agreements protect your designs and your competitive advantage.

For defence, infrastructure, medical, and technology products, this is not negotiable.

-

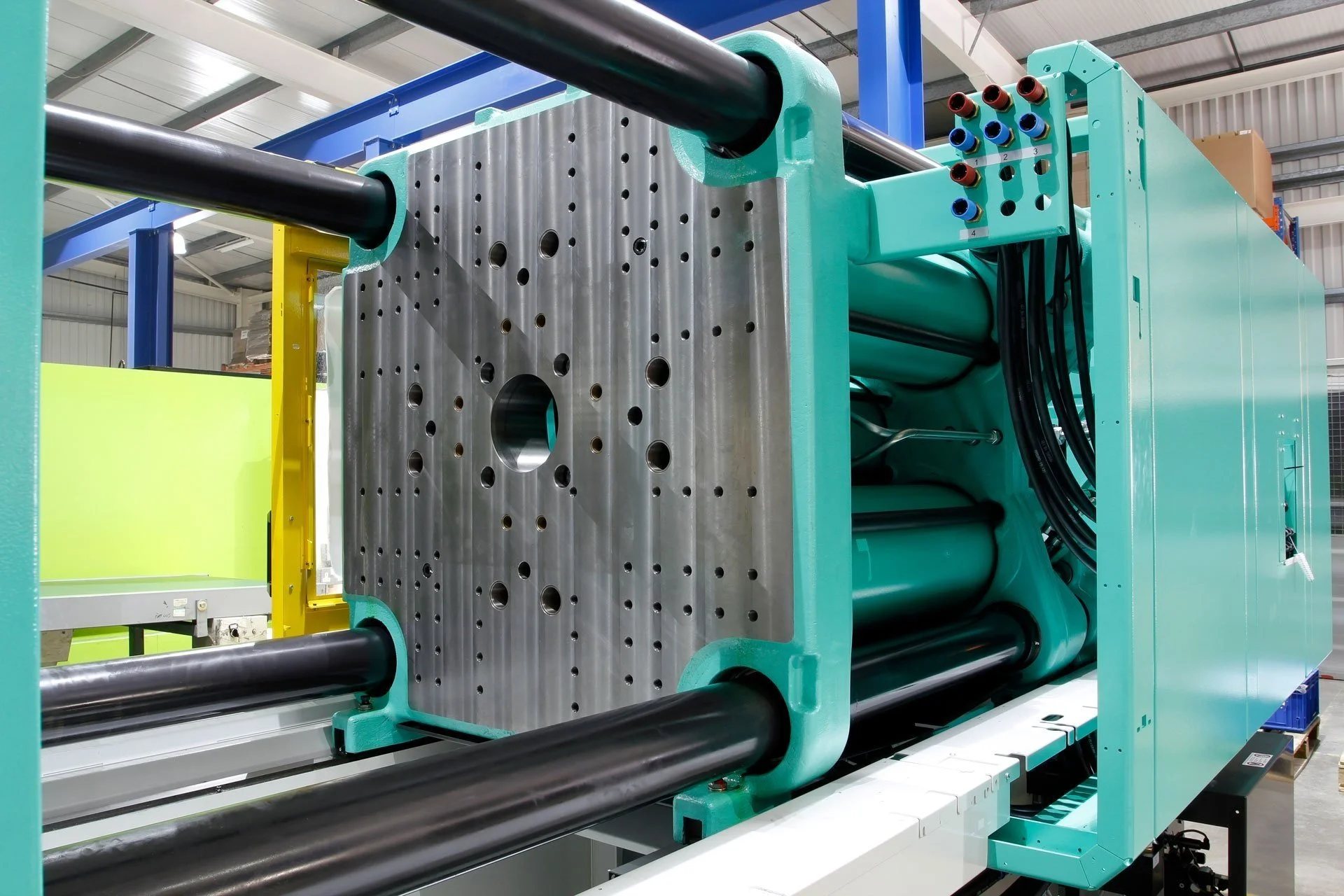

Why Choose Plastic Injection Moulding

Plastic injection moulding is ideal for products that need to be made at scale with consistent quality.

Once tooling is right, injection moulding delivers repeatable parts, tight tolerances, and reliable performance across thousands or millions of units.

When injection moulding is combined with good design, proper tooling, and controlled processes, it becomes one of the most efficient and reliable manufacturing methods available.

Australian injection moulding adds the benefit of local support, faster adjustments, and better oversight.

-

Australian Injection Toolmaking Specialists

Tooling is where many projects succeed or fail.

Poor tooling leads to slow cycles, inconsistent parts, and ongoing headaches. Good tooling makes production boring, and boring is exactly what you want.

Australian toolmakers design tools to suit the product, the material, and the expected production volume. If changes are needed, they can be made quickly. If maintenance is required, support is local.

This flexibility is critical for products that evolve or scale over time.

A Simple 3 Step Manufacturing Process

Step 1: Review the product

Design, materials, and requirements are checked to make sure the product can be manufactured properly and consistently.

Step 2: Build and validate tooling

Tooling and prototypes confirm fit, function, and quality before full production starts.

Step 3: Produce and supply

Injection moulding runs with controlled processes, reliable lead times, and consistent output.

Ready to Manufacture Your Product Locally

If you are looking for a plastic manufacturer in Australia, the real question is not who can mould plastic.

It is who can reduce risk, communicate clearly, protect your IP, and deliver consistently over time.

If you want to talk through whether local manufacturing makes sense for your product, volumes, or timelines, that conversation is usually the best place to start.

Contact B&C Plastics to discuss your product and see if Australian manufacturing is the right fit.