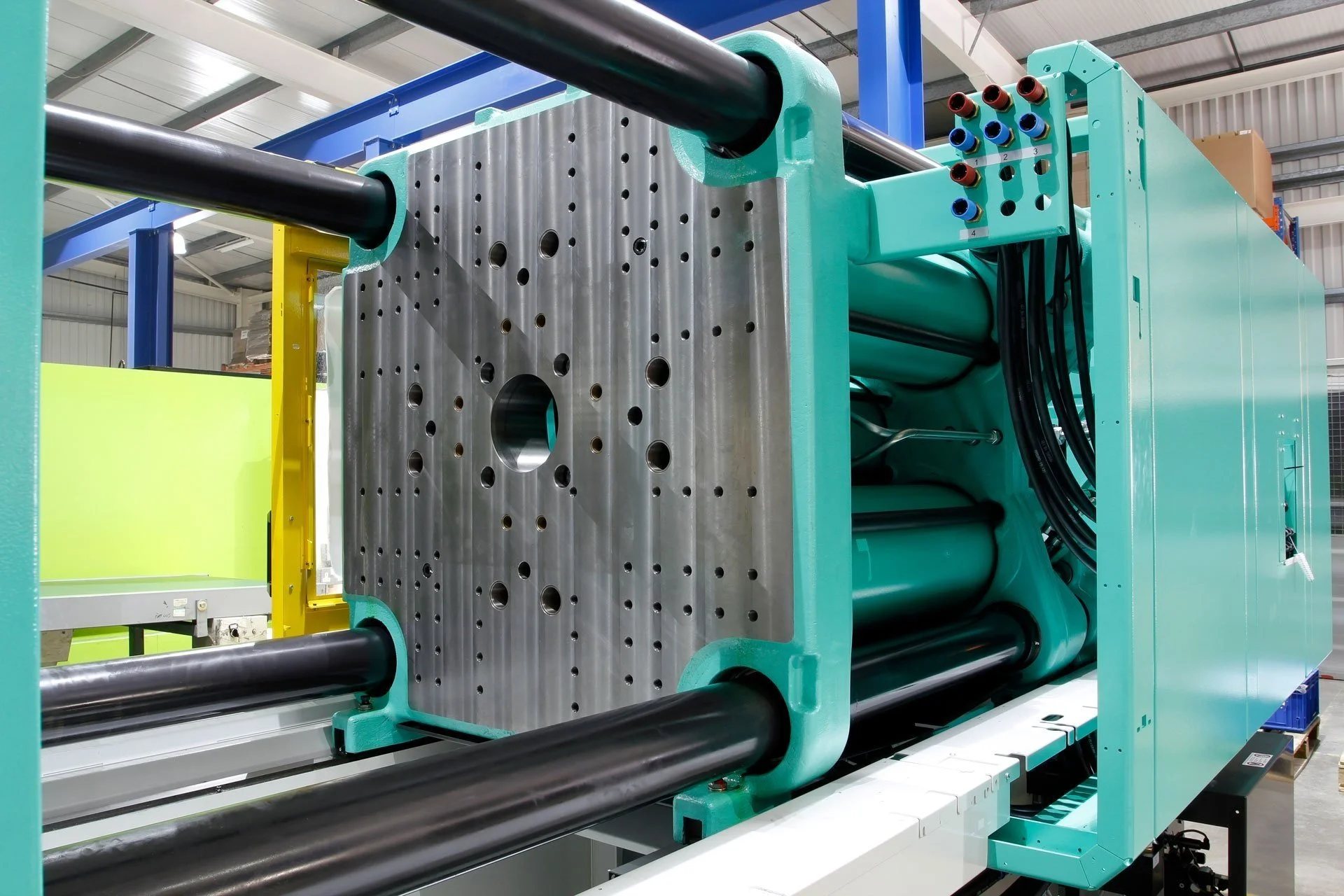

Why Outsourcing Beats Buying Your Own Injection Moulding Machine

If you are asking whether you should buy your own injection moulding machine or outsource production, you are already asking the right question. For most Australian businesses, outsourcing wins. Not because machines are bad, but because running injection moulding properly is harder, more expensive, and more distracting than people expect.

Buying a machine feels like control. In reality, it often creates new problems you did not plan for.

This page explains why most serious businesses choose outsourcing, when buying a machine does make sense, and how to think about the decision clearly before spending a lot of money in the wrong place.

The Short Answer

Buying an injection moulding machine only works if:

You have constant, predictable volume

You already have experienced moulding staff

You are prepared to manage quality, downtime, compliance, and maintenance long term

If any of those are missing, outsourcing is usually the better option.

That is why so many Australian companies end up partnering with engineering-led manufacturers like B&C Plastics instead of running moulding in-house.

Combining full ISO certification with DISP accreditation, B&C Plastics provides high-quality, secure, and traceable plastic injection moulded components engineered for reliability and performance.

Key Benefits of Outsourcing Injection Moulding

Outsourcing is not about giving up control. It is about avoiding problems you do not want to own.

Meet the Team

-

Lower Manufacturing Costs

The biggest mistake people make is thinking the machine is the main cost.

It is not.

The machine is just the start.

Once you go in-house, you also pay for:

+ Tooling design and maintenance

+ Operators for every shift

+ Process engineers when things go wrong

+ Scrap, rejects, and rework

+ Power, floor space, safety systems

+ Compliance, audits, and documentation

+ Downtime when someone is sick or a machine fails

Most businesses underestimate these costs badly.

Outsourcing turns all of that into a known production cost. No surprise repairs. No idle machines. No expensive learning curve.

That is why outsourcing usually saves money over time, even if the part price looks higher at first glance.

-

Consistent Quality and Fewer Headaches

Injection moulding is not just pressing a button.

Quality depends on:

+ Process control

+ Material handling

+ Tool condition

+ Operator experience

+ How problems are diagnosed and fixed

This is where in-house setups often struggle.

When one key person leaves, quality drops. When demand spikes, shortcuts happen. When machines sit idle, problems creep in.

Professional manufacturers live inside these systems every day. They have documented processes, trained teams, and quality checks built into production, not added at the end.

That consistency is hard to maintain in-house unless moulding is already your core business.

-

Scalable Production Without Guessing

Buying machines forces you to guess the future.

Buy too small and you hit a ceiling. Buy too big and expensive equipment sits unused.

Outsourcing removes that gamble.

You scale production up or down based on demand, not assets. That matters if your volumes change, your market shifts, or your product range grows.

For companies producing anywhere from 10,000 parts to over a million parts a year, flexibility beats ownership almost every time.

-

Access to Real Expertise, Not Trial and Error

Machines do not solve design problems. People do.

Outsourcing gives you access to:

Engineers who know how plastics behave

Toolmakers who know what will fail later

Process specialists who know how to stabilise production

Teams who work with recycled materials properly

CNC prototyping and machining when designs need fixing

Trying to build this knowledge in-house takes years and a lot of expensive mistakes.

Most businesses do not want to become plastics experts. They want good parts, delivered on time, without drama.

-

Faster Time to Market

Setting up in-house moulding takes time. Often much more than planned.

Outsourced manufacturers are already running machines, managing materials, and producing parts every day.

That means:

+ Existing tooling can often be running in weeks

+ New products follow a clear development path

+ Problems are solved faster because the team has seen them before

If speed matters, outsourcing usually wins.

-

Sustainability and Compliance Are Easier With the Right Partner

Recycled content, APCO targets, ESG reporting, ISO compliance, security requirements. These are now normal, not special.

Doing this properly requires systems, documentation, and experience.

Good manufacturing partners already have:

+ Certified quality systems

+ Traceability for materials

+ Processes for recycled plastics

+ Documentation that stands up in audits

Trying to build this internally just to support one or two products rarely makes sense.

-

Production Support and Clear Accountability

One underrated benefit of outsourcing is having someone else accountable for outcomes.

Instead of managing:

+ Operators

+ Schedules

+ Quality issues

+ Delays

+ Customer pressure

You deal with one point of contact who owns the result.

That makes life easier for procurement, engineering, and management teams alike.

How It Usually Works

Step 1: Project fit check

volumes, timelines, compliance needs

Step 2: Engineering and planning

tooling, materials, production setup

Step 3: Repeat production

forecast-driven supply with consistent quality

Simple. Predictable. Fewer surprises.

When Buying Your Own Machine Can Make Sense

There are cases where buying a machine is the right move.

It can work if:

Volumes are extremely high and stable

Parts are simple and unlikely to change

You already have skilled moulding staff

Compliance requirements are minimal

Downtime risk is acceptable

These situations exist, but they are rarer than people think.

Most businesses that rush into buying machines eventually outsource anyway after experiencing the reality.

Frequently Asked Questions

Still looking for answers? Give our friendly team a call on (07) 3208 0544 or pop in for a visit!

-

Not when you include labour, downtime, scrap, maintenance, and compliance. Outsourcing is usually cheaper long term.

-

No. You gain control over outcomes instead of equipment.

-

Yes. It is often the best way to validate products before scaling.

-

Certified Australian manufacturers typically offer stronger IP protection than in-house setups and far more than offshore suppliers.

The Real Decision

The real choice is not machine versus outsourcing.

It is whether you want to:

Run a plastics manufacturing operation or

Focus on your products, customers, and market

Most successful businesses choose the second option.

If you are currently thinking about buying injection moulding machinery, it is worth talking to people who run it every day before committing capital.

If you want to sanity-check volumes, timelines, costs, or whether outsourcing makes sense for your situation, contact B&C Plastics for a straightforward project fit conversation. No sales pressure. Just clarity.

Owning machines feels like control. Owning outcomes is what actually matters.